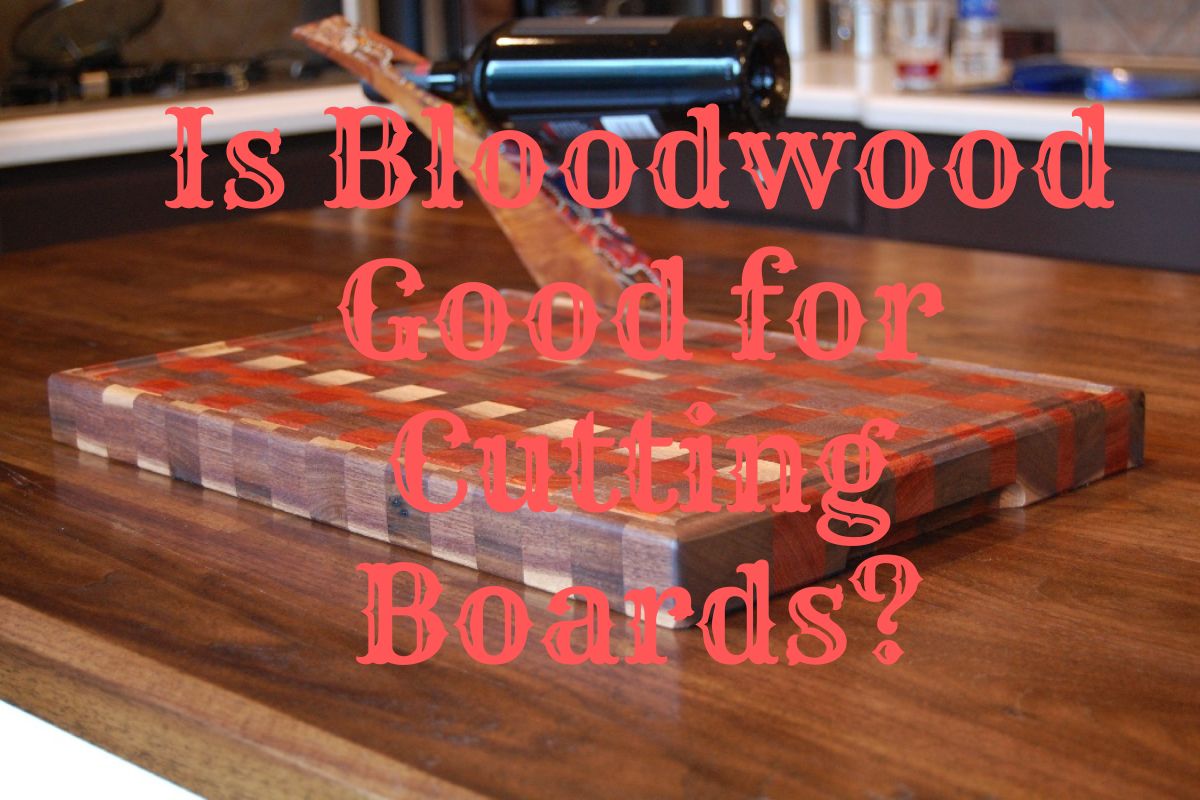

People looking for something exotic to use as cutting boards may ask: “Is bloodwood good for cutting boards?”

Bloodwood is great for cutting boards. Despite being an imported wood species and some challenges during manufacturing, bloodwood will make great cutting boards because of its amazing strength and impressive density.

Bloodwood is also very hard and very heavy which means it is stable when used as a chopping board for meats, vegetables, and fruits. The repeated motion of the knife edge as you cut all kinds of food will never affect the surface of bloodwood and thus you have a cutting board that will last a long time.

What is Bloodwood?

Bloodwood is known by many names and one of these is satine. Bloodwood is a term used to describe wood with extreme red grains and has species such as Brosimum paraense, Brosimum lanciferum, and Brosimum rubescens.

Bloodwood has a pale orange-red to a very deep red color. The difference between bloodwood and other woods with striking red color is that bloodwood retains its hue and can become darker as the wood ages. Many red-colored woods tend to lighten as they age.

Bloodwood is from the many species of Brosimum which is native to Brazil, Peru, Panama, Venezuela, French Guiana, Suriname, Guyana, and Colombia. This lovely wood belongs to a group of woods known as exotics and is sold in markets in the United States as such.

People who have worked with bloodwood or have used it for various projects swear that it is an experience. The heartwood remains bright red even after construction and can grow deeper in hue over time.

This wood has straight to slightly interwoven grains. The heartwood may form ribbon stripes of yellow, red, or green and is very visible when the wood is quarter sawn. The bloodwood sapwood is pale yellow and is very clearly separated from the heartwood.

What are the Characteristics of Bloodwood?

Bloodwood is not just great for cutting boards. It is also an amazing exotic wood to make carvings, inlays, guitars, trims, and much more. As you can see, bloodwood is mostly used to make decorative items but not used in construction projects. This is because of its extreme hardness and many challenges in woodworking. Let us get to know more about bloodwood in this guide.

Bloodwood – Brosimum rubescens

Bloodwood is satine and Brazilwood. It is a popular imported wood species with impressive physical characteristics and amazing strength.

- Distribution: Bloodwood is native to tropical South America

- Tree Dimensions: 80 to 150 feet high and 4 to 7 feet wide

- Average Dried Weight: 66 pounds per cubic feet

- Specific Gravity: .90, 1.05

- Janka Hardness: 2900 pounds-feet

- Color or Appearance: Bloodwood has a very bright or vivid red heartwood. This heartwood color can become darker and more pronounced as the wood ages. Bloodwood must not be exposed to light as this can darken quickly. The sapwood is pale yellow. The trunk is very large and the sapwood is seldom seen in lumber.

- Grain or Texture: Bloodwood grain is very straight but there are also times these are slightly interlocked. This wood has a fine texture and a lovely natural shine. Bloodwood is chatoyant or may have a changing luster because of a narrow band of light that hits the surface of the wood.

- Resistance to Rotting: Bloodwood is very dense and thus, it is resistant to rotting, decay, and molds. This wood is also resistant to insect attacks especially termites and other burrowing insects.

- Workability: Bloodwood is very dense and thus, can blunt or gum up cutters, knives, and blades. The wood is brittle and thus, may splinter when worked. Only a few woodworkers prefer to work with bloodwood and those who can stand it will be rewarded with an amazingly lustrous red surface.

- Presence of Odor: Bloodwood emits a mild scent when it is being worked.

- Toxicity: There are reports that working with bloodwood can cause skin irritation. Wood dust from bloodwood can lead to thirst, nausea, and increased salivation.

- Availability: Bloodwood is available as wide boards for large projects and smaller squares and blanks for turning projects. Bloodwood boards come with a dull reddish-brown color so choose only pieces with a blood red hue. This is imported hardwood so expect to pay a higher price than other hardwood species.

- Common Uses: Bloodwood is commonly used in the manufacture of trims, inlays, guitars, turned objects, and knife handles. It is also good wood for cutting boards and other similar kitchen tools. There is also furniture made from bloodwood but these are mostly very hard, heavy, and dense.

Here are Other Woods Related to Bloodwood:

Snakewood – Brosimum guianense

Snakewood has a stunning appearance. It is called snakewood because of the lovely speckles and blotches that look like snake skin. People who have worked with snakewood agree that the patterns on the wood resemble hieroglyphics which is why many call snakewood letterwood.

Aside from its natural color and impressive appearance, snakewood is also very dense and very hard. It belongs to the list of the densest woods in the world. Snakewood is also comparable to lignum vitae as the world’s heaviest commercial woods.

- Distribution: Snakewood is native to the coastal areas of northeast South America

- Tree Dimensions: 65 to 80 feet high and 6 to 12 inches wide

- Average Dried Weight: 75.7 pounds per cubic feet

- Specific Gravity: .96, 1.21

- Janka Hardness: 3800 pounds-feet

- Color or Appearance: Snakewood is known for its amazing snakeskin-like patterns or designs. The wood is reddish-brown with patches that contrast the wood grain. The color of snakewood will become darker and even homogenize as the wood ages and when the wood is constantly exposed to the UV rays of the sun.

- Grain or Texture: the grain of snakewood is straight. This comes with a fine and even texture. Expect high natural shine across the surface.

- Resistance to Rotting: Snakewood is very durable to rotting, mold, and decay. It is also very resistant to burrowing insects such as termites. However, it is not used for outdoor applications.

- Workability: Snakewood is very hard to work with. Because the wood is very dense, it can blunt or gum out blades, knives, and cutters. This wood is very brittle and thus, can splinter easily. Extreme care is important when you’re cutting or working with snakewood. This wood may be hard to work with hand and power tools but it accepts glues, finishes, and paint really well.

- Presence of Odor: Snakewood has a mild smell when worked. The scent is very similar to bloodwood’s odor.

- Toxicity: There are reports of people who have suffered skin and respiratory symptoms while working with snakewood.

- Availability: Snakewood is a very rare and small tree and thus, it is one of the most expensive woods in the world. The price for milled and surfaced snakewood with exquisite snakeskin patterns is the most expensive. Meanwhile, other sections of the wood are sold for a much more affordable price. These are often sold under the term “armourette.” Snakewood is sold in half and full logs. Pith checking is selecting the best part of the snakewood for specific projects and these can lead to severe wastage.

- Common Uses: Snakewood is very popular in making decorative items. It is used to make violin bows, knife and tool handles, and turned objects. Snakewood is also used to make inlays and veneers.

Jicarillo – Brosimum spp

Jicarillo is known to be related to snakewood. It is a very dense hardwood native to Central America. It is scientifically called Brosimum guianensis but some say that it is a species of the Eschweilera. The wood called Eschweilera Mexicana is also called jicarillo.

- Distribution: Jicarillo is native to Honduras

- Average Dried Weight: 63 pounds per cubic feet

- Specific Gravity: .77, 1.00

- Janka Hardness: 2360 pounds-feet

- Color or Appearance: Jicarillo comes with light to medium red-brown heartwood with dark black streaks found throughout the grain. The sapwood is sharply demarcated and is gray-white in color.

- Grain or Texture: Jicarillo grain has a uniform fine to moderate texture and has a lovely natural shine.

- Resistance to Rotting: Jicarillo is resistant to rotting, burrowing insects, and mold.

- Workability: Jicarillo is very hard to work with just like snakewood and bloodwood.

- Presence of Odor: this wood has no characteristic smell.

- Toxicity: there are no reported health risks and allergic reactions when working with the jicarillo wood.

- Availability: Jicarillo is available only in small blanks used for turning projects and also craft blanks. This is imported hardwood and thus, expect a very high price for it.

- Common Uses: Jicarillo is useful as furniture. You’ll find jicarillo tables, chairs, and cabinets. It is also useful in small objects such as knife scales, cutting boards, turned objects, and many more.

How to Work with Bloodwood?

Bloodwood is extremely hard to work with but this quality has not stopped woodworkers from using this wood in many woodworking projects. Here are some tips to help you work with bloodwood.

Always Use Sharp Tools

To work with very dense and heavy woods like bloodwood, you must always use very sharp tools. This goes without saying that you should sharpen your tools and planers if you plan to work with bloodwood and other dense hardwoods.

But no matter how sharp your tools are, these will eventually gum up and dull so you may need to work extra hard and sharpen these again. Your plane and blades will work better plus, you’ll give yourself a break from all the hard work.

Use Bloodwood That Has Been Quarter Sawn

It is always best to quarter saw bloodwood and other dense hardwoods. This cut will allow you to face the plane easier compared to using a flat-sawn stock. The reason for this is that all woods possess weaker bonds from the radial plane. Thus, planing the wood’s radial face is easier compared to planing the growth ring face.

In a flat sawn wood, the growth rings of the board are wider while the radial plane is at the edges. Face planing flat sawn wood such as dense wood is very hard. You need the patience to do this. However, planing the piece’s edges is easier.

Always Rough Cut Closer to the Project’s Final Size

When working with very dense woods like bloodwood, follow this cutting tip. All wooden boards have imperfections like twisting, crooked sections, cupping, bowing, and more. Hand planing these issues can take time.

But by crosscutting the wood piece into shorter lengths and cutting it into narrow pieces, the effect of the warping will be greatly reduced and it will be much easier to remove these defects. Cut the wood close to its final dimensions while the piece is still rough to reduce your hand planing efforts.

Add Water to the End Grain

Aside from using a razor-sharp blade or planer, you should wet the end grain to open up the grains of really hard woods like bloodwood. Some woodworkers recommend using alcohol but this can evaporate easily. Some may also use mineral spirits but some recommend using clean water.

As much as possible, don’t plane immediately after wetting the end grain. Allow the water to seep through the fibers and to soften the wood.

Don’t Chop, Bore, and Saw Only

Avoid chopping bloodwood and other very dense hardwoods, you must bore and saw only. This is because dense wood species are not too compressed along the grain and thus, every blow and chop of the chisel will not penetrate far compared to a less dense wood.

But if you don’t have time or you want to speed up the process, you can use power tools instead of hand tools. If you’re using a coping saw or turning saw, cut closer to the baseline.

Don’t Hurry Bloodwood

Working with bloodwood and other dense hardwoods will simply take longer. Pieces like bloodwood may splinter if you’re not careful. This is why woodworkers take their time to preserve their stock, their tools, and their energies.

How to Care for Bloodwood Cutting Boards?

How do you care for cutting boards made from one of the strongest woods in the world? The trick is to clean your board before, during, and after each use. Even if bloodwood is strong, dense, and hard, you still need to care for it to ensure that this will last a lifetime.

Clean wooden cutting boards at once

Even if your cutting board is made of dense wood like bloodwood, it will still have pores where food debris and dirt can get stuck. And when food becomes stuck inside these pores, bacteria and other microorganisms can grow. Preparing your food on these boards can lead to illness and other health issues.

Thus, it’s best to clean your cutting boards after every use. Wipe it clean if you’re just cutting dry food like bread. For wet, raw, and sticky food, wash the board with dishwashing soap and running water immediately. Dry the wooden board by wiping the surface with a clean towel and air drying it.

Clean your wooden cutting boards by hand.

Do not use the dishwasher to wash a wooden cutting board. The extreme heat inside the dishwasher plus chemicals in the soap you’re using can make your board warp. Also, heat can open up the pores and destroy the wood fibers. Even if your cutting board is made of dense wood like bloodwood, the wood fibers can eventually become damaged.

Use ordinary dishwashing soap and water.

Never use strong detergent soaps to clean wooden cutting boards. It would be best to use dishwashing liquid soap to clean the surface. Use clean flowing water to flush out all the soap. Do not soak a wooden cutting board in water and soap. You may dunk it in water and then rinse it immediately.

Use a soft scrubber to remove all food debris.

You may use a soft foam scrubber to gently scrub the surface of a wood cutting board. The scrubber will not hurt dense woods like bloodwood but will only sweep away the dirt and grime and leave the surface dirt-free.

Careful when preparing smelly food

The problem with wooden chopping boards is that they can accumulate odors. So, if you’re cutting smelly food like garlic, onions, and cheese, you must clean your board as soon as you’re done. Wash this in soap and water. But if the smell persists, you can use lemon juice to get rid of it.

Chop a whole lemon in two and take one half and gently scrub it on the surface of the chopping board. You may also use white vinegar to get rid of nasty smells.

Remove stains right away

Another issue with wooden chopping boards is that these can easily accumulate stains coming from food. Stains from onions, meats, fruits, and other vegetables can be very hard to remove. Sometimes, you don’t have any choice but to throw away the chopping board.

You can remove stains easily by using baking soda. Take a box of baking soda and place these all over the surface of the board. Take special attention to the area where the stains are. Use a clean cloth or towel and place this over the baking soda and scrub the stain away.

Use the towel to wipe the excess baking soda and then rinse the board well. If the stain persists, use more baking soda.

Have a separate cutting board for meat and produce

A good practice is to use a separate cutting board for produce and meat. This will help prevent bacteria and other foodborne illnesses. Meat, seafood, poultry, eggs, and fish must be separated from dry food as these may have juices that may seep onto the chopping board.

Air dry wooden cutting boards

Always air dry your wooden cutting boards. If you can, place these out in the sun to dry completely. You can also hang them to dry or just place them against a wall to dry naturally.

Oil wooden cutting boards to preserve their shape

Oiling wooden cutting boards is a way to keep the surface free from marks and dents. The oil also makes the surface waterproof and makes the lovely surface last a long time. Now there are many ways to oil a cutting board and this depends on the cutting board oil to use.

The best oil is food-grade mineral oil. Don’t use cooking oil, coconut oil, vegetable oil, or palm oil as these will only turn rancid. The rancid smell, taste, and feel of oil may stick to the food you’re preparing and affect its taste, smell, and flavor.

How to Prevent Color Changes in Bloodwood?

Bloodwood color is one of the most exotic. Most people who have worked with bloodwood try to preserve its color with the following strategies.

Avoid direct sunlight if you’re preserving furniture made of bloodwood. UV rays in sunlight can significantly affect the color of the wood.

Apply finish on the wood surface. A good quality finish will keep the surface in good shape and prevent cuts, marks, and scrapes. Experts recommend an exterior-grade spar varnish product as this comes with UV inhibitors to keep sunlight away.

For bloodwood cutting boards, don’t use your board if you want to preserve it. This wood may be strong and durable but if you constantly expose it to water, soap, food, and dirt, you will end up ruining it.

Final Words

Bloodwood is great for cutting boards. It is strong, durable, and hard and thus, it can withstand constant abuse as you cut food. However, bloodwood is still wood. If you abuse this wood using heat, UV rays, and harmful chemicals, you can end up ruining it.

There are many species of bloodwood and two of the most popular are snakewood and Jicarillo. The two species have almost the same qualities and characteristics as bloodwood. These species are strong, hard, dense, and have amazing beauty. Lastly, snakewood and Jicarillo are like bloodwood as these are also expensive exotic woods. Consider these qualities when buying furniture or items made of these woods.

Leave a Reply