What do you know about MDF vs HDF? When deciding on a material to use for a project, you can be tempted to use a material with a higher level of durability. However, this is the time that you correct this kind of perception because choosing the best product should not always depend on durability. This should also be considered when choosing between MDF and HDF. So, what are the things that you need to know about MDF and HDF?

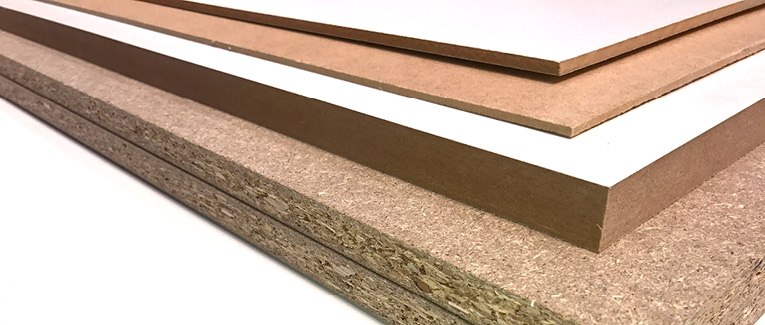

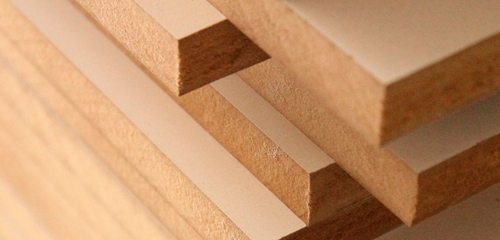

HDF (high-density fiberboard) is a composite panel that has been present for so many years already. MDF (medium-density fiberboard), on the other hand, is built from wood particles joined through adhesives.

MDF materials are commonly sanded smooth before they are processed to become their finished products like wall coverings or furniture panels.

So, what is it that you need to learn about these two types of the board?

Differentiating MDF and HDF

It pays to know and understand the difference between MDF and HDF. The fact is that these materials are very alike in several ways. However, if you use MDF in place of the HDF, or vice versa, there is a big chance that your project will not turn out well.

Both materials are often used in tabletops and cabinets. However, their distinction from each other can be distinguished from their cost-effectiveness, manufacturing, and installation.

Perhaps the biggest distinction between MDF and HDF is that the latter is manufactured from wood strands. MDF, on the other hand, begins with a thicker wood strand known as “Plywood” rather than wooden fibers. The plywood is subjected to a series of coarse actions until such time that the wood fibers are eliminated, keeping the board with the grain only.

MDF is quite more affordable compared to HDF. The density of HDF is more hence it is a lot thinner, making it unideal for parts assembly. Both materials are not waterproof. This is the reason why these materials should never be used in areas that are prone to moisture or water. However, it is good to note that MDF can be waterproofed and HDF has more resistance to water.

The density of MDF ranges from 600 to 800 kg/m3, while HDF’s density is 800 kg/m3. This explains why HDF is a lot heavier and more durable compared to MDF. Nevertheless, the density specification of MDF has given it the advantage for cutting.

MDF and HDF Uses

Considering the versatility of MDF, there is no wonder that this material has many uses. MDF is durable, sturdy, and affordable. Furthermore, its structure is polished giving you an invariable feeling whenever you are working on a project with it. Some of the uses of MDF are the following:

- Countertops – this material is ideally used in countertops because of its heat-resistance ability of up to 200 degrees Celsius. The MDF is very workable for this project and can look sophisticated in the house.

- Chairs – MDF is perfect when making chairs – whether for your home or the office. Chairs built from MDF are comfortable to sit at. They do not take in liquids or retain odor, and of course, they look great!

- Other Uses – MDF has few other uses. It can be used when building cabinets or shelves, flooring in toilets or washrooms, decorative objects, speaker exterior, creating showpieces, building furniture, for the roof’s second layer, and providing fire resistance.

You can say that HDF possesses the qualities of MDF, but with sturdiness and durability at a higher level. However, HDF is quite expensive because of its strength. Given its extra strength, the field of application alters. Some of the common uses of HDF are the following:

- Kitchen Cabinet – the HDF board will make good material for kitchen cabinets because of its moisture-resistance ability. It also does not take in odors. Also, with the manner it is designed, people can easily create a shaped cabinet.

- Countertops – this material can also be used for countertops. It does not require a high level of maintenance. You can easily use any type of saw to cut it or shape it.

- Bathroom – you might know already that wood is an ideal moisture conductor. Hence, you should not have the same material in your kitchen and bathroom. Sadly, bathrooms are prone to getting wet and your walls, cabinets, and other areas could easily trap moisture. Using HDF can solve these issues since it is water-resistant.

- Coffee Tables – coffee tables could come in different designs and shapes. You can use HDF when making coffee tables in your home since this material does not take in liquids or odors. Hence, it will be easy for you to clean the mess left on the table.

- Other Uses –HDF has few other uses. It can be used for door skins, laminate flooring, backing panels, high-use fittings, regularly used furniture, roofing shingles, cladding, wall, stairs, and more.

Things to Remember

So, when you are about to choose between MDF vs HDF, you might need to go back to its main features.

If you are looking for something that could provide greater durability to reinforce heavyweight, then you should use HDF. However, if you are just starting to explore carpentry and want to shape and trim your board, then it would be ideal if you use MDF. However, just remember not to put a lot of weight on the MDF.

As mentioned, HDF can work excellently on numerous projects. It is superior quality but affordable. You can confidently use it in any part of the house that requires durable flooring. Perhaps, the only thing you need to consider in using this material is that it couldn’t appear as traditional or genuine as other board types offered in the market nowadays.

The MDF board has some edges over HDF. It is more resistant to moisture and heat. Nevertheless, remember that it also carries several disadvantages. You should understand that there is no such thing as perfect when looking for a solution to your construction need. The solution will always depend on your preferences and requirements for a specific project.

Leave a Reply