There are many types of wood available but have you ever thought about using composite wood? What is composite wood and where does it come from? Let’s find out in this composite wood guide.

What is composite wood?

There’s no end to man’s insatiable need for wood. This building material is strong, aesthetically pleasing, and durable, however, it’s becoming close to impossible to return forests to their natural states. It’s high time to find other ways, other materials that can replace wood.

Enter composite wood, an alternative that’s cost-efficient, environmentally friendly, and versatile. Composite wood is made up of derivative wooden products made by combining the fibers and strands of different wood.

Composite wood is also called engineered wood, manmade wood, and WPC or wood-plastic composite wood. WPC is when the wood is mixed with thermoplastics to improve its strength, density, and usability. Aside from wood fibers and grains, composite products are also developed from organic fibers like vegetables or those containing lignin. These are sugar cane, rye, hemp, and wheat with polymers and wood flour integrated to enhance processing.

How composite wood is made

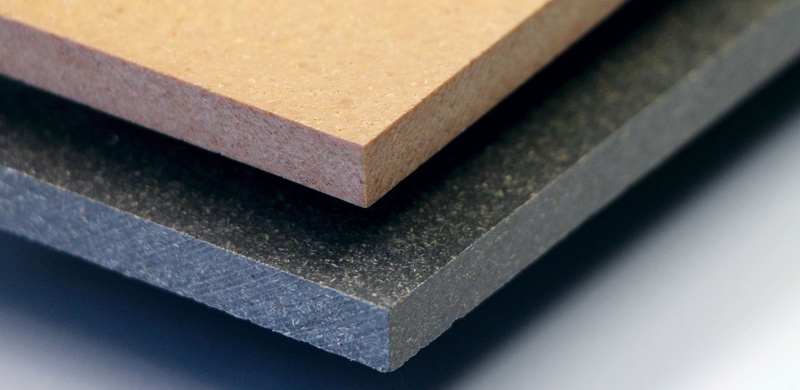

Wood composite products are made from various hardwoods and softwoods that are utilized for lumber or building materials. These are mixed with milled wooden particles and heated resin made of thermoplastic material.

Some wood processing sawmills and companies combine the mixed wood particles and resin and transform these into pellets. These pellets are melted and manufactured into the shape that the customer needs. This is a far more extensive process compared to just mixing and extruding the particles to form the final shape.

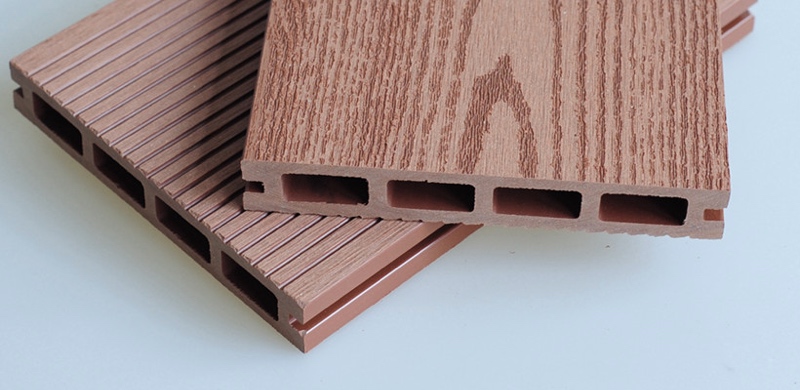

In WPC materials, virgin and also reused thermoplastics are included; usually, polyethylene plastics are used to make WPC. You can make composite materials in different colors by adding colorants, UV stabilizers, and other agents. It is also possible to make hollow and solid-shaped WPCs.

What makes composite wood better than natural wood?

Composite wood is selected by more and more builders and contractors because of its many amazing qualities:

Composite wood is very durable

Because you are combining the properties of different hardwood and softwoods you used to create composite wood, this product is indeed more durable and more efficient compared to natural wood.

The components of composite wood are also natural wood and thus, it has retained most of its properties. In some cases, the wood polymer is combined with other materials like plastics/thermoplastics which also enhance its hardness, durability, and longevity.

Composite wood is less expensive than natural hardwood and softwoods.

Composite wood is made from scraps, cuttings, and other leftover parts of natural wood. Therefore, it is less expensive to use composite wood. And despite an extensive manufacturing process, composite wood is just a fraction of the price of the same size as hardwood or softwood material.

Composite wood is weather-resistant when properly sealed and painted

Just like natural wood, you can paint over composite wood or use a wood sealant to protect the surface. And because of these, you are properly sealing the wood and improving its weather-resistant properties.

Composite wood is also made from other materials such as polymers and plastics and these add to the hardness and strength of the material and improves its weather–resistance qualities as well.

Composite wood is available in many shapes, sizes, and textures

You can find composite wood in different shapes, sizes, and even finishes/textures. You may even request a specific color or the size you want to use for your construction. Also, you can decide on the texture of the composite wood if you want to use one to make furniture pieces, flooring, interior walls, decorative pieces, etc.

Composite wood may be designed to meet the qualities your industry needs

Composite wood may be manufactured according to your industry, business, or construction needs. If you need a strong composite material for building then you can order composite wood according to your specifications. Additives and other chemicals are included in the manufacturing process to meet your needs.

Composite wood requires no special tools and equipment to use.

Just like regular wood, you don’t need to use special cutting equipment and finishing tools to work with composite wood. You may use ordinary fastening tools like a hammer, drill, or power tools and use regular cutting equipment like table saws, reciprocating saws, and many more. Finishes, stains, and paints used in finishing regular wood may be used on composite wood.

Some drawbacks of using composite wood

As there are many benefits of building with composite wood, there are also some drawbacks that you should keep in mind.

Composite wood may need more energy to produce or manufacture

Because you need to mill, use adhesives, press, and melt composite wood particles, you need more energy to produce it compared to regular natural wood that will only need cutting or shaping. However, the cost of processing composite wood is still a fraction of the cost of natural hardwood and softwoods.

Composite wood may contain toxic chemicals

The most important disadvantage that you must consider when using composite wood is the adhesive as well as other additives used to process it. In some cases, these chemicals may be released into the air when the material is cut and thus, could be harmful to health.

To counter these disadvantages, people working with composite wood use protective gear including masks and goggles to avoid inhaling these toxic chemicals. Also, buy composite wood only from manufacturers who adhere to standards. This means their products are safer as they contain less toxic chemicals.

Composite wood is a versatile, quality building material used for general construction and in the home décor and furniture industry. It is a common building material chosen by many contractors and builders but use is not without risks. Now that you know what is composite wood, you now have an idea about its many benefits and some drawbacks. You may now confidently decide if this is the right building material for your home or business.

Leave a Reply