When finishing wooden furniture, you’ve probably encountered a product known as Danish oil. What is Danish oil? Why is it the most popular furniture oil for wood furniture? Let us find out if Danish oil is the real thing or if it’s just hype in this Danish oil furniture polish guide.

What is Danish Oil?

Danish oil is finishing oil made from polymerized linseed or tung oil. There is no specific formulation for this oil. Every manufacturer has its specific formula.

Danish oil is preferred by many woodworkers because it’s a hard-drying oil. This means it can polymerize into a solid oil when mixed with oxygen. You will get a satin finish that’s water-resistant and hard-wearing. You can use this as a primer over bare wood before you apply varnish or paint.

Where Does Danish Oil Come From?

Danish oil is a combination of linseed oil or tung oil, synthetic resin, mineral spirits, and varnish. The ingredients make this oil very durable and easy to use.

What are the Advantages of Using Danish Oil?

Danish oil is one of the top furniture polishes and oils to finish wooden furniture. There are so many reasons why this oil is the choice among furniture makers and hobbyists. Let’s focus on the many advantages of using Danish oil.

It Provides Amazing Protection Against Liquids

Danish oil is very resistant to water as well as other kinds of liquids. It coats the wood so it becomes waterproof, not just splashproof. This oil is waterproof because of its ability to polymerize small wood particles. It covers all minute particles so the surface becomes strong and very resistant after drying.

Water molecules cannot penetrate polymerized surfaces so you can use your wood furniture outdoors or in environments where there is high moisture. You can use Danish oil to create a strong protective layer on furniture like patio chairs and tables, benches, shelves, and desks. You can also use Danish oil over wooden decks, flooring, and wooden fences.

Aside from being water resistant, Danish oil is also alcohol resistant. You can wipe and sanitize with alcohol desks and tables coated with Danish oil. You can also count on Danish oil’s flood-resistant characteristics and therefore, it is a good finishing oil and polish for dining tables and desks.

This Oil Dries Quickly

Danish oil also dries quickly compared to other finishing oils and polishes. According to experts, the average time finishing oil will take to dry is about 6 hours however, this can vary depending on the environmental temperature and humidity.

But if the weather is cooler, you may need to wait a long time for Danish oil to completely dry. Cooler weather and much lower humidity can slow down the drying time of any kind of finishing oil. It is also possible that the drying times of Danish oil vary depending on the manufacturer.

Therefore the Danish oil manufactured locally may have shorter or longer drying times compared to oils manufactured elsewhere. So, if you’re using Danish oil to finish your wooden project, follow the manufacturer’s instructions on project drying times.

The most will take about 3 days under average temperature and humidity. If you’re going to apply multiple coats of Danish oil, make sure to dry one layer first before applying the next layer, and so on.

This is Non-Toxic Safe Oil

Most finishing products such as varnishes are very toxic to health. Despite being effective in sealing and protecting wood, these varnishes can be hazardous to health, especially when inhaled. These products can burn your upper respiratory system and affect your breathing. You can lose consciousness when you inhale this product especially when you’re applying this in an enclosed area.

This won’t happen with Danish oil. Danish oil is non-toxic and as an example, you can apply this oil on children’s toys, desks, and household furniture. You won’t encounter any health issues whether you apply several coats.

Danish oil does not contain any toxic ingredients or additives. After curing, the furniture or the decorative item may be used indoors or outdoors. Always remember to wait for the oil to completely cure no matter where you applied it.

Some Danish oil comes with a label: “non-toxic once cured.” This means that you need to wait for the oil to completely cure before using the furniture piece.

Danish Oil is Food Safe

Another advantage of Danish oil over other finishing oils is it’s safe to use on kitchenware and tableware because it’s food safe. You can use Danish oil on wooden kitchen tools like rolling pins, bowls, serving dishes, ladles, etc. Danish oil is safe on cutting boards, cupboards, spice racks, salad bowls, and much more.

But again, always wait for the oil to dry and cure completely before using these. You need to wait for the oil to polymerize. Once the oil has been completely cured, it won’t be released into food or into the environment as the oil has bonded with the wood polymers.

The curing process for wooden items used to prepare and serve food may take longer than the curing time for furniture making. It may take several weeks to cure Danish oil as it takes time for it to bond with the wood polymers and become inert.

Woodworkers who use Danish oil say that the wait is worth it. Once the curing time is over, you’ll enjoy preparing, serving, and eating food on well-finished kitchen utensils and tableware.

Enhances Wood’s Natural Sheen

Wood that has been finished with Danish oil will look and feel better. This oil will not just protect the furniture but will make it look luxurious and delicate. Danish oil can absorb wood polymers and protect them from any defects. It protects the exterior and the interior part of the wood by keeping it from any damage like marks, scratches, cuts, and dents.

The glossy appearance plus the darker color produced by applying Danish oil on wood creates a spectacular look. Aside from protection from physical damage, Danish oil can improve wood’s heat resistance and chemical resistance.

You’ll feel some kind of sticky oil on the surface of the wood that’s treated with Danish oil. This is the main reason why this oil leaves a lovely sheen. This is the effect you want for rustic home décor, decorative tables, picture frames, clocks, jewelry boxes, and other decorative items.

For best results, woodworkers recommend applying around 3 coats of Danish oil. After applying a coat, dry it completely first. You can apply the next one after the first layer has completely dried. Also, some woods may need several coats of Danish oil before you can achieve the right shine. More coats of this oil mean longer drying times.

Easy to Use Furniture Polish

Danish wood is also one of the easiest to apply to any wooden project. You don’t need a special tool to apply it. With a paintbrush or a piece of cloth, you can effectively apply Danish oil to any piece of furniture or wooden project. Applying it towards the direction of the grain is necessary to allow the oil to penetrate the surface of the wood.

Depending on the type of wood you’re working on, you can apply 3 coats to get the best results. Also, the wood type you’re using matters when considering the number of coats necessary.

We recommend applying at least 3 coats for the best results depending on the wood type. Once the first layer is dry you may now proceed with the next coat. To find out if the wood is dry, touch the surface and see if there are any wet spots. Drying times for every coat may take 3 to 6 hours or more.

Amazing Elastic Capabilities

Danish oil creates an elastic surface on the wood. All wood will contract or expand due to age, exposure to excessive temperatures and humidity, and other factors. But Danish oil will protect these woods plus will stretch depending on the shape of the wood. And this elastic capability of Danish Oil will never fail even when the wood is cured and started to polymerize.

Danish oil can contract or expand together with wood and this won’t affect the final appearance or finish. This oil will never lose its protective qualities and in fact, this will remain the same.

This elastic characteristic of Danish oil can be compatible with most wood. This is impossible with other finishing oil brands. You can guarantee that there will be no cracks, scratches, and dull areas on the wood because of the application of Danish oil.

Use Danish Oil as Primer

Aside from using Danish oil as finishing oil, this oil can also be used as a sealer or primer. Apply Danish oil before using finishers and paint. You can mix this oil with other oil-based paint. Remember, let the Danish oil surface dry completely before adding your sealer or primer. When using Danish oil, you can make your wood last for a long time.

What are the Disadvantages of Using Danish Oil?

As with other oils, there are some disadvantages to using Danish Oil. This natural oil can protect wood however, it needs regular maintenance, is less durable, and can be time-consuming to use. Consider these disadvantages when selecting the right oil to finish your wooden project.

Danish Oil Needs Regular Maintenance

Danish oil needs regular maintenance. You need to clean the piece regularly to preserve its lovely shine. Maintenance includes removing dust, grime, and dirt. This is because the polymeric properties of this oil can attract dust and dirt particles. But don’t worry, these particles won’t penetrate the wood. These will only settle on the surface and can make the pieces dull. Therefore, keep your Danish oil-treated wood pieces dust-free and away from dirt and grime.

To clean surfaces finished with Danish oil, use a shammy cloth. Fold the cloth into a thick piece and use this to wipe the area clean. If you spot any cracks, scrapes, and scratches, apply another coat of Danish oil.

When to re-apply Danish oil? It would be best to apply Danish oil to your wood pieces every year. Use two to three coats of oil per year to keep the pieces looking fresh and new.

Not as Durable as Other Oils

Danish oil works well with almost all types of wood however, it is not the most durable finish. There are other wood finishing products that can provide better protection against scratches, marks, and cuts.

Even if it can protect wooden pieces and furniture, the cracks and cuts may reappear after some time and thus, you need to reapply this oil once again.

A better alternative to Danish oil is tung oil. This produces a more durable and lasting finish and is not toxic as well. And since Danish oil works like a magnet, attracting dust and dirt daily, you may need to clean this consistently. We will discuss a few finishing oils that are deemed better than Danish oil.

Application is Time-Consuming

Danish oil application is a painstaking process as you need several coats to get the best results. And don’t forget that you need to wait at least 3 days for each layer to dry before applying another coat of oil.

Also, the drying time can depend on the kind of Danish oil that you’re using as well as the furniture or wooden object you’re treating. For every coating, tedious sanding is needed on the area using 600 grit sandpaper. Most woodworkers recommend applying 2 to 3 coats for the best results on different woodworking projects. All-in-all, you need to invest a lot of time, and patience, to use Danish oil in your project.

If you’re applying Danish oil on a project or item that you will regularly use, have an alternate item. Don’t use the item until the Danish oil has completely dried and cured.

Applies Only On Bare Wood

Danish oil works best on untreated wood only. This is because this oil needs to penetrate the wood fibers and change the wood structure to produce the best effects.

If you apply this on treated wood, finished wood, or painted wood, it won’t work at all. The oil will only drip and wash away when the item is rinsed with water. Also, the oil will take a very long time to dry without penetrating the wood’s surface.

When Danish oil is applied to untreated wood, the oil penetrates well and binds to the wood pores. In very porous woods, Danish oil can penetrate the wood structure easily and becomes a problem. Once the oil is inside the wood structure, the strength of the wood will decrease.

You will also notice cracks and minute scratches will appear on the surface. Therefore, don’t use Danish oil on finished wood and also on wood with large pores such as maple, basswood, alder, birch, and willow wood.

Also take note that after applying Danish oil, the wood tone or the surface will change into a much darker color. Thus, testing is needed before applying the oil all over the furniture or the wooden object you wish to finish. Check this on a hidden part of the furniture such as the back or the sides.

Extremely Flammable

Woodworkers and hobbyists who use Danish oil are always careful about cleanup after completing a project. When Danish oil is exposed to air and reacts with oxygen, it can make the surface of the piece harder. This is good but this oil can become very volatile and flammable as it is a blend of hydrocarbons distilled over petroleum.

Danish oil is flammable and thus, you must always be careful when working with this oil. Do not use it near a fire. The rags and brushes you use to apply the oil must be cleared after use. If you don’t, these can dry and can easily catch fire. These can react with oxygen in the air and spontaneous combustion may happen.

Dispose of used rags and brushes properly. Before throwing these away in the trash, make sure to soak these in water and clean them. Do not keep these laying around in your garage or shop as these can cause fires.

Will Not Smooth the Wood Grain

Another disadvantage of Danish oil is that it does not smoothen the grain at all. Thus, after every coat of Danish oil, you need to sand to achieve a smooth surface. Also, if you use a brush to apply Danish oil, sanding can remove brush marks before applying the next coat.

Sanding is an essential part of working with Danish oil. It requires the right sandpaper grit to get the best results. The best grit is 600 for this project. After sanding, wipe the surface with a damp cloth and then, a dry one to remove all wood dust. You must use a tack cloth or vacuum the area using a shop vac to get all the dust out before applying the next coat.

Other Danish Oil Alternatives

As we said earlier, other finishing products can provide better protection than Danish oil. Here are some of them:

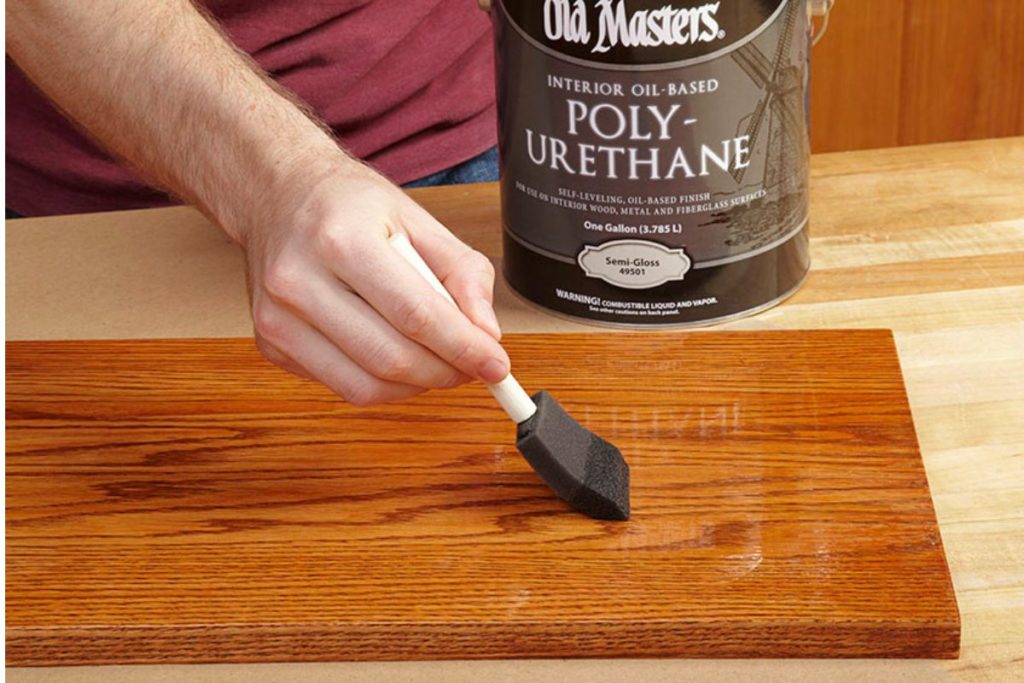

Polyurethane

Polyurethane is a plastic finish in liquid form. It dries well and provides a strong and durable finish on the surface of the wood. Polyurethane finishes are available in water-based and oil-based products and are also in glossy or satin finishes.

Water-based polyurethane is more in-demand than oil-based polyurethane because it smells better and is less toxic. It is available in clear color and thus, applying this will not affect the wood’s regular color and appearance. Also, water-based polyurethane dries faster than oil-based products.

Shellac is water-based polyurethane that will not hold well with chemicals and heat. It is best for picture frames, desks, bookcases, and side tables; these furniture and decorative items won’t be used in extremes.

When it comes to oil-based polyurethane products, always use a respirator mask and work in a well-ventilated space. You can apply both oil and water-based polyurethane on acrylic or latex paints.

Tung Oil

Tung oil is a plant-based wood finish so it is safe to use. It is clear, easy to dry, and can penetrate deep into the wood grain. Tung oil protects wooden furniture, décor, and flooring very well. This finishing oil is the favorite among furniture craftsmen in the United States and many other countries.

Tung oil is best on maple furniture to be used when linseed oil is not available. It can penetrate even a dense grain and it also dries clear. Also, most furniture made from cherry and walnut woods is finished with tung oil.

Varnish

Varnish is a collective term for a clear and transparent protective coating or film applied on wood. Varnish is not a stain but has a yellowish shade due to the manufacturing and the kind of material used to make the varnish product.

Woodworkers use varnish to keep the wood free from scratches, cuts, marks, and abrasions. It is a great way to waterproof wood and keeps boring insects and moisture away. Varnish works well over tables, desks, and cabinets.

Paint

Paint is the best way to protect the wood but of course, it will change the color of the wooden furniture or piece. There are two kinds of wood paint finishes oil-based and latex. Latex paints provide longer-lasting protection compared to oil-based paints and thus, it is best for furniture and also for interior surfaces.

A primer is needed before applying paint. Primer will smooth out all imperfections before a fresh coat of paint is applied.

Final Words

Danish oil is a wood finishing oil that’s from tung oil or linseed oil. This oil is suitable for all types of wood and can provide a lovely finish and good protection against discoloration, insects, and moisture. However, there are also some disadvantages when working with Danish oil including increased maintenance, reduced durability, and much more.

Considering the many qualities, pros, and cons of Danish oil use can make it easier to decide if this is the right wood finishing product to use for your projects.

Leave a Reply