When it comes to cutting a polycarbonate sheet, the process might seem challenging at first, but with the right tools and techniques, you can achieve precise results.

Starting with the correct equipment and safety gear is essential, but the real key lies in understanding the scoring and snapping methods for cleaner cuts.

Before you begin your project, consider the various cutting techniques available to make sure your polycarbonate sheet is trimmed efficiently and accurately.

Key Takeaways

- Use appropriate tools and techniques for cutting polycarbonate sheets safely and accurately.

- Securely clamp polycarbonate tubes and use the right saw blade for clean cuts.

- Prioritize safety measures, including protective gear and proper ventilation.

- Finish cut edges meticulously by sanding, deburring, and inspecting for a polished result.

Tools Needed for Cutting Polycarbonate Sheets

To cut a polycarbonate sheet accurately, you’ll need a circular saw or jigsaw with adjustable speed for the best results.

When cutting polycarbonate, safety goggles are a must to protect your eyes from any flying debris.

It’s important to use the appropriate saw blade for each tool; for circular saws, a fine tooth saw blade is recommended, while non-ferrous metal blades work best for jigsaws when cutting polycarbonate sheets.

Before you begin cutting, make sure to place the polycarbonate sheet on a supportive board to prevent any bending or flexing during the cutting process.

Leaving the protective film on the sheet while cutting helps maintain its surface integrity and ensures clean cuts.

Additionally, applying masking tape along the cutting line serves as a guide for more precise cuts.

Remember to adjust the speed of your saw according to the thickness of the polycarbonate sheet for the best results.

Scoring and Snapping Techniques

Begin the scoring process on the polycarbonate sheet by using a utility knife to create a shallow cut along the desired cutting line.

Make sure the knife blade is sharp to achieve a clean cut. The scored line weakens the polycarbonate sheet, making it easier to snap.

Apply firm pressure while scoring, but be cautious not to cut too deeply to prevent damage to the sheet.

Once the scoring is complete, gently bend the sheet along the scored line to snap it. Make sure to support both sides of the sheet evenly to avoid uneven breaks.

Snapping the polycarbonate sheet should result in a smooth and precise cut.

This method works best for straight cuts on thinner polycarbonate sheets.

Take your time to score accurately and snap evenly to achieve a neat finish without jagged edges.

Remember, precision is key when using the scoring and snapping techniques for cutting polycarbonate sheets.

Circular Saw Cutting Method

For precise and clean cuts on polycarbonate sheets, employ a circular saw with a fine-toothed blade.

Adjust the saw’s speed to about 4,000 revolutions per minute for best cutting performance.

Secure the polycarbonate sheet on a supportive board and clamp it tightly to prevent any movement during cutting.

Before cutting, apply masking tape along the cutting line to act as a guide for the saw, ensuring straight cuts.

When ready, slowly and steadily guide the circular saw along the marked cutting line.

Avoid applying excessive pressure to prevent cracking or splintering of the polycarbonate sheet.

The fine-toothed blade will help minimize chipping along the edges of the cut.

Remember to wear appropriate safety gear, including goggles and a mask, to protect yourself from any debris created during the cutting process.

Jigsaw Cutting Technique

To begin mastering the jigsaw cutting technique for polycarbonate sheets, focus on selecting a fine-toothed blade suitable for this material.

Mark your cutting line accurately to guide the jigsaw along the desired path.

Remember to prioritize safety by wearing appropriate gear such as goggles and gloves.

Blade Selection Tips

Considering the necessity for precise cuts when using a jigsaw to cut polycarbonate sheets, have you selected a fine-toothed saw blade suitable for cutting non-ferrous metals?

It’s vital to choose a blade designed for cutting plastic materials to avoid chipping or cracking.

Opt for a medium cutting speed on the jigsaw to guarantee effective and smooth cuts.

Control the pressure and speed of the cut to maintain accuracy and prevent the sheet from moving.

Secure the polycarbonate sheet in place using glue clamps along the cutting line to minimize any potential shifts and guarantee precise cuts without compromising the integrity of the material.

Cutting Line Marking

Have you ever wondered how to accurately mark the cutting line on a polycarbonate sheet for precise jigsaw cutting?

To guarantee accuracy and precision, use a straight edge and a marker to mark the cutting line clearly on the sheet.

A well-defined cutting line is essential to guide the jigsaw along the desired cutting path, ultimately leading to clean and precise cuts.

Precision in marking the cutting line is critical, as it helps maintain the quality and accuracy of the cut when using the jigsaw technique.

Safety Gear Importance

When using a jigsaw to cut polycarbonate sheets, ensuring you’re equipped with proper safety gear is paramount to safeguarding against potential eye injuries and maintaining personal safety.

Safety goggles are essential to protect your eyes from flying debris, while gloves safeguard your hands during the cutting process.

Wearing a dust mask is essential to prevent inhalation of plastic dust, and ensuring proper ventilation helps disperse any fumes generated.

Prioritizing safety gear, including goggles, gloves, a dust mask, and adequate ventilation, greatly reduces the risk of accidents and promotes a secure cutting experience with a jigsaw.

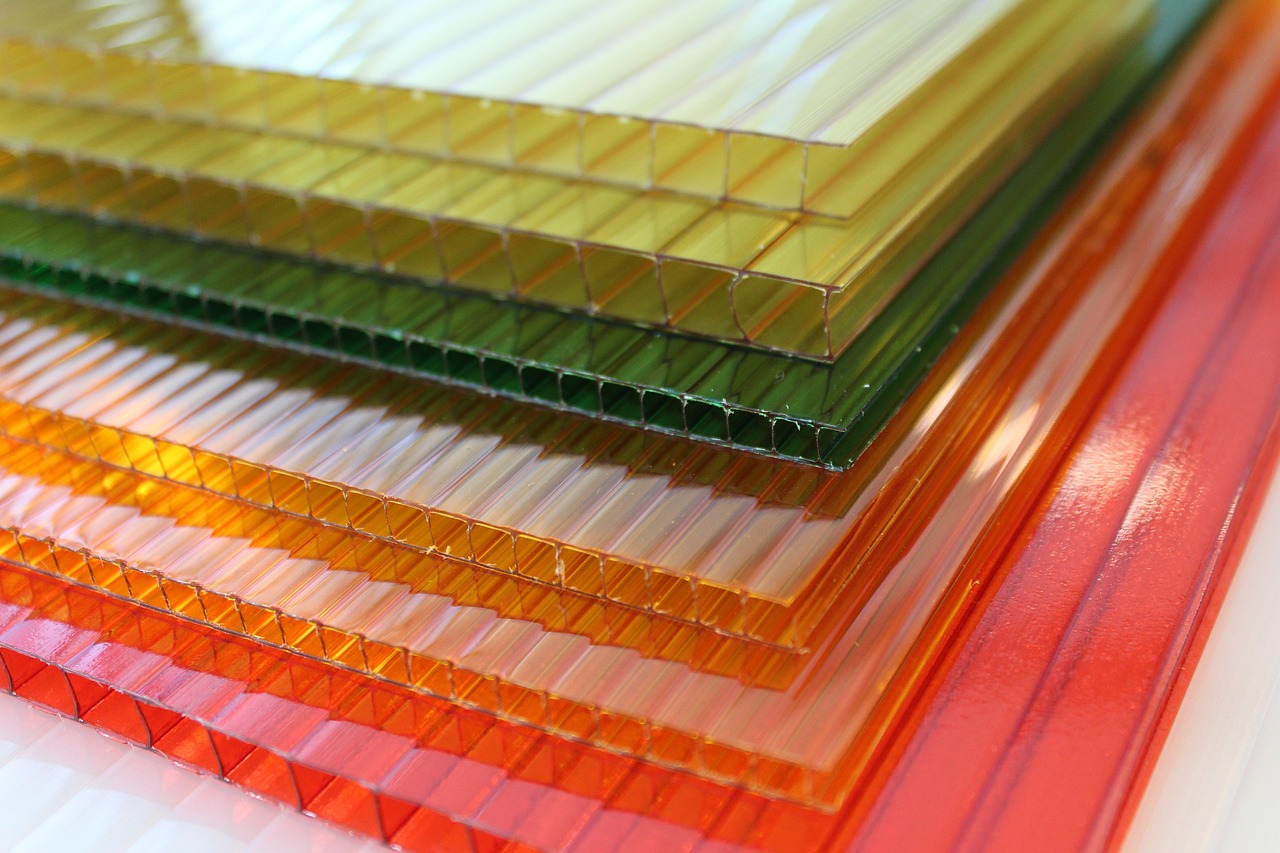

Cutting Corrugated Polycarbonate Sheet

To cut corrugated polycarbonate sheets effectively, use a fine-toothed blade on a jigsaw for precise and clean cuts.

Secure the sheet firmly in place with clamps before cutting to guarantee movement accuracy.

When cutting along the corrugated lines, do it carefully to maintain the structural integrity of the sheet.

For longer, straight cuts on corrugated polycarbonate sheets, consider using a circular saw with a fine-toothed blade for efficiency. This method helps in achieving accurate results.

After cutting, remember to sand the edges to guarantee a smooth finish and reduce the risk of sharp edges that could cause injuries.

By following these steps and using the right tools, you can effectively cut corrugated polycarbonate sheets with precision and achieve the desired outcome for your project.

Cutting Thick Polycarbonate Sheet

For cutting thick polycarbonate sheets effectively, consider using a circular saw equipped with a fine tooth blade for precise and clean cuts.

Secure the polycarbonate sheet with clamps and provide support near the cutting line to minimize vibrations.

Opt for a slow cutting speed to maintain control and prevent cracking or chipping.

Apply steady pressure throughout the cutting process, starting from the edge with a pilot hole for accuracy.

When using a circular saw, it’s important to avoid exerting excessive pressure on the tool to prevent damage to the material.

By maintaining a steady hand and a consistent cutting speed, you can achieve smooth and professional results.

Remember to provide proper support under the sheet to prevent any bending or flexing during cutting.

Following these guidelines will help you cut thick polycarbonate sheets with precision and efficiency.

Cutting Polycarbonate Tube

To cut a polycarbonate tube effectively, make sure to properly secure the tube using clamps to prevent any movement during cutting.

Use a fine tooth saw blade and control the jigsaw speed for a smooth and precise cut.

Remember to wear safety goggles and adhere to the correct cutting techniques to maintain safety while working with polycarbonate tubes.

Tube Preparation Tips

How can you guarantee the precise cutting of a polycarbonate tube?

When cutting polycarbonate tubes, use a fine-toothed saw blade designed for non-ferrous metals.

Confirm the tube firmly in place with clamps or a vise to prevent any movement during cutting.

Opt for a jigsaw with adjustable speed settings for enhanced control and precision.

Apply masking tape along the cutting line to serve as a guide for the saw and prevent surface scratches.

Verify that the jigsaw blade moves smoothly through the tube to prevent chipping or cracking.

These steps will help you achieve accurate and clean cuts when working with polycarbonate tubes.

Cutting Techniques

When cutting a polycarbonate tube, make sure the tube is securely clamped in place to prevent any movement during the cutting process.

Choose a fine-toothed saw blade suitable for cutting non-ferrous metals to ensure a smooth cut.

Utilize a jigsaw at medium speed to effectively cut through the polycarbonate tube.

Apply consistent pressure along the cutting line to prevent any cracking or splintering of the material.

To enhance precision, consider using glue clamps to secure the tube in place before cutting.

These clamps will help maintain control over the cutting process and guarantee a clean, accurate cut on the polycarbonate tube.

Safety Measures

For heightened safety when cutting a polycarbonate tube, make sure you’re equipped with safety goggles, gloves, and a dust mask to protect against debris and particles.

Use a stable work surface and secure the tube with clamps to prevent movement during cutting.

Make certain to have proper ventilation in the work area to avoid inhaling any fumes or dust generated during the cutting process.

Consider employing a fine-toothed blade on a jigsaw or a specialized tube cutting tool for precise and clean cuts on polycarbonate tubes.

Always adhere to the manufacturer’s guidelines and recommendations for cutting polycarbonate tubes to guarantee safety and accuracy.

Safety Precautions During Cutting

To guarantee safety during cutting, prioritize wearing safety goggles, gloves, and a dust mask to protect your eyes, hands, and lungs.

Proper ventilation in the work area is vital to prevent inhaling fumes or dust particles.

Secure the polycarbonate sheet with clamps to keep it firmly in place and avoid any movement that could lead to accidents.

When cutting, be cautious not to apply excessive pressure to the cutting tool, as this can cause the sheet to crack or splinter.

Always adhere to the manufacturer’s safety guidelines for the specific cutting tool being used to minimize risks and ensure safe operation.

By following these safety precautions diligently, you can reduce the chances of injuries and create a safer cutting environment for yourself.

Achieving Fine Finishes

For a polished and professional look, utilize a fine tooth saw blade when cutting polycarbonate sheets to achieve fine finishes.

The fine tooth saw blade will help you make precise cuts with clean edges.

When cutting, remember to apply light pressure to the saw to make sure that the polycarbonate sheet doesn’t chip or crack.

This gentle approach guarantees that the sheet remains intact and the edges come out smooth.

Once the cutting is complete, sand the cut edges to further refine them and achieve a flawless finish.

After sanding, clean the edges with a damp cloth to remove any debris or dust particles.

Inspect the cut edges thoroughly for any signs of damage.

Address any imperfections promptly to maintain the quality of the finished product. By following these steps and using the right tools, you can achieve fine finishes when cutting polycarbonate sheets.

Removing Rough Edges

Sand the cut edges of the polycarbonate sheet with fine-grit sandpaper to smooth out any roughness present.

Utilize a deburring tool to eliminate sharp edges left behind from the cutting process.

Remember to wipe the edges clean with a damp cloth to guarantee no debris or dust remains, maintaining a clean finish.

Sanding Rough Edges

Begin by smoothing out the rough edges of the polycarbonate sheet using sandpaper to achieve a clean and professional finish.

Sanding with fine-grit sandpaper helps to eliminate any burrs or sharp points that may be present after cutting the sheet. This process is important not only for aesthetics but also for safety, as it reduces the risk of injuries from handling the sheet.

Heat Polishing

To achieve a smooth and polished finish on a cut polycarbonate sheet, consider employing heat polishing as a method to effectively remove rough edges.

Using a heat gun or propane torch, you can soften and smooth the edges of the polycarbonate sheet.

Carefully apply the heat source in a controlled manner to melt and reshape the rough edges, creating a professional look.

This process helps eliminate sharp edges and burrs that may be present after cutting.

Remember to maintain a safe distance and consistent movement with the heat source to prevent overheating or damaging the polycarbonate material.

Heat polishing serves as a final step in the cutting process, enhancing both the appearance and safety of the sheet edges.

Using the Deburring Tool

Achieving a smooth and polished finish on a cut polycarbonate sheet involves using a deburring tool to effectively remove rough edges and guarantee a clean, professional outcome.

After cutting the sheet along the designated line, rough edges and burrs may be present, which can compromise the quality of the cut.

By using a deburring tool, you can carefully smooth out these imperfections, ensuring a clean and smooth cut.

This process not only enhances the visual appeal but also eliminates any sharp edges that could pose a safety risk.

Incorporating the use of a deburring tool into your post-cutting care routine is essential for maintaining the integrity and safety of polycarbonate sheets.

Leave a Reply